I had the privilege to be part of Sombra Mezcal right when their new distillery was being built in Oaxaca, Mexico (World Capital of Mezcal). There, we had the opportunity to create a production system that both honored tradition and integrated the latest technology available. Photography: Karen Cuevas

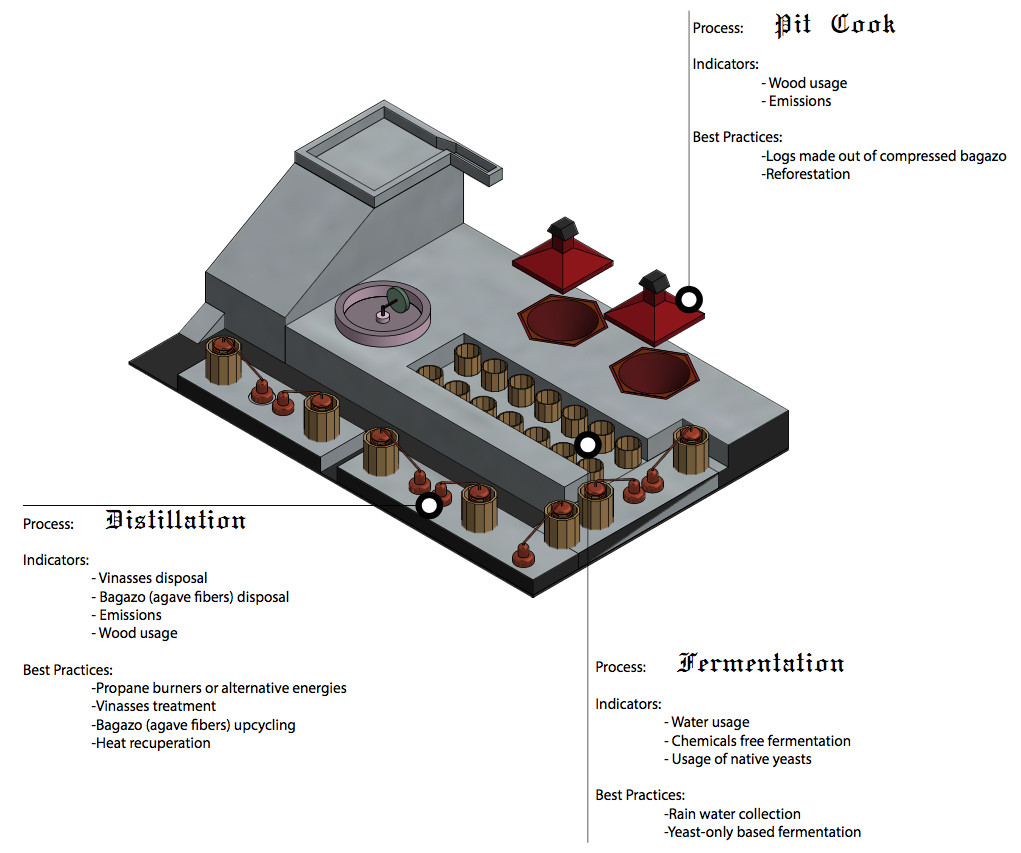

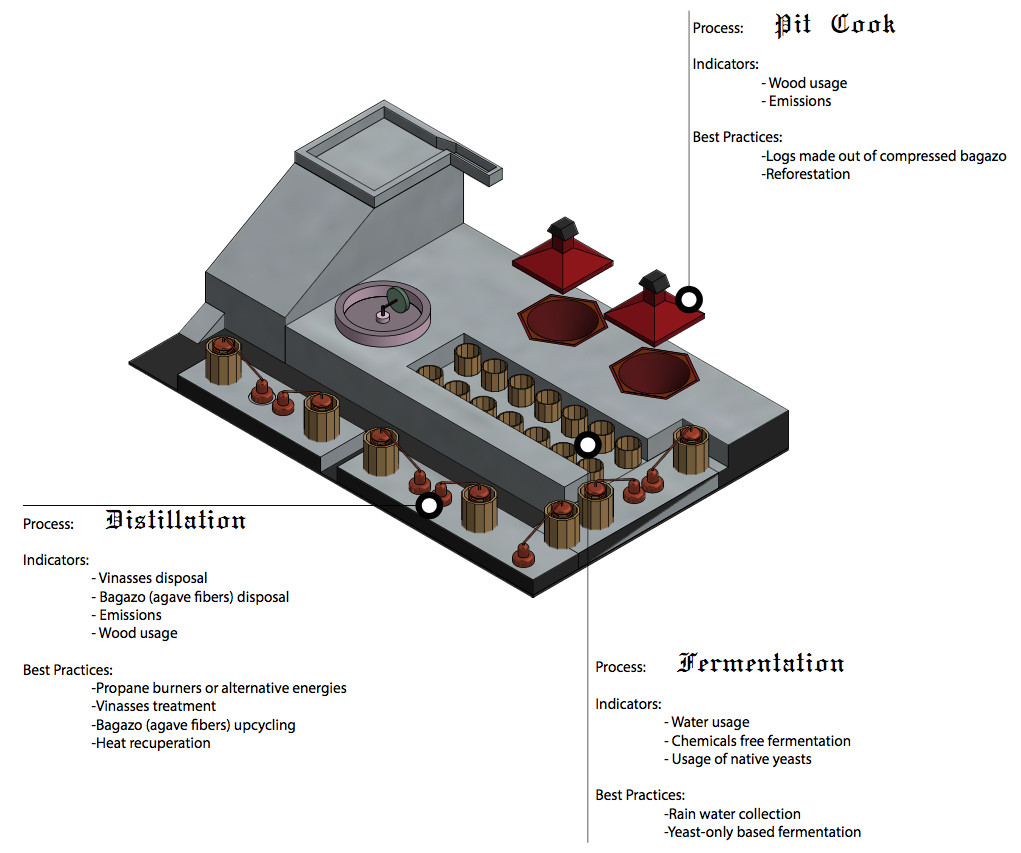

With the guidance of Master Sommelier Richard Betts and COO John Sean Fagan, the Sombra distillery's team carefully designed every part of the mezcal making process: from selecting the best agave to repurposing its fibers and vinasses.

One of my main areas of work at Sombra was to design equipment used for distillation (in collaboration with Xaquixe) and establish temperature curves to achieve precise and delicious cuts. Here I'm revising the first distillation kiln with Miguel, who, due to his eye for detail, was in charge of building all seven of them. Photography: Domenica Gallinatti

Sombra Mezcal is double distilled in 100% copper stills. All seven stills were fully handmade and locally sourced.

Clean agave hearts can weigh more than 60 kgs each. Many of them are harvested deep into the mountains, where not even horses or donkeys can help.

In the process of roasting agave hearts inside an earth pit; transforming their starches into fermentable sugars.

Regarding waste management I initiated the program to upcycle leftover agave fibers into compressed adobe bricks. Bringing back an old and effective technique that was almost forgotten after concrete got in the way. To optimize the traditional process an hydraulic compressor was acquired to merge dirt, fibers and vinasses into long-lasting insulating bricks.